Source

Although cacao originated in Mesoamerica, it is now grown around the globe between the 20th parallels, along the equator. As cacao is our main ingredient, finding the best bean is paramount. There is nowhere to hide when you are making two ingredient chocolate so we have to find the best cacao in the world and then try to get some!

Obtain

Finding good cacao is one thing, getting it is another. The logistics behind getting a ton of cacao from the other side of the Andes to Portland is quite a feat in itself. Every source has its own hurdles and getting small quantities (less than a full container) presents all kinds of fun problems.

Sort

We sort through every bean to make sure that only the best beans get through. Different sources give us beans in different states of cleanliness. Our clean bean award goes to the beans from the San Jose Estate in Gran Couva Trinidad! They arrive polished, consistent and beautiful! It is a pleasure to plunge your hands into the sack and feel the beautiful cocoa.

Roast

Roasting is where we get to add our signature to the chocolate we make. We adjust our roast profiles to bring out the most exciting flavors a bean has to offer. We roast 30lbs batches in our squad of Royal drum roasters. Made in upstate New York around 1910, these roasters are beautifully ornate workhorses. With two Royals dedicated to nuts and one more dedicated to cacao, the neighborhood is treated to delightful waves of roast cacao.

Crack & Winnow

After we roast we have to separate the hull from the nib with a machine that manipulates air pressure and gravity to isolate the lighter hull from the fat laden nibs. We only use the nibs to make our chocolate and the leftover hull makes great mulch but we feed ours to some pigs in Salem, OR.

Refine & Conch

The nibs are then ground and aerated to further develop the flavor profile and

ideal mouth feel of the chocolate. The size and the shape of the tiny particles are very important to the melt and the flow. Refining makes the particles the desired size; conching aerates and tumbles the particles, rounds the edges and evenly coats everything with the beans' own cocoa butter. This assures a great release of flavor and texture as the chocolate melts on your palate.

Age

Chocolate, like wine, continues to develop as time passes. The first few weeks are when the most obvious change in flavor occurs. Then it plateaus. Chocolate, if kept free of moisture, is very stable and could sit for years and still be good. We let our chocolate sit until it is ready before we cast it into bars. But when you get it, just eat it. It’s ready.

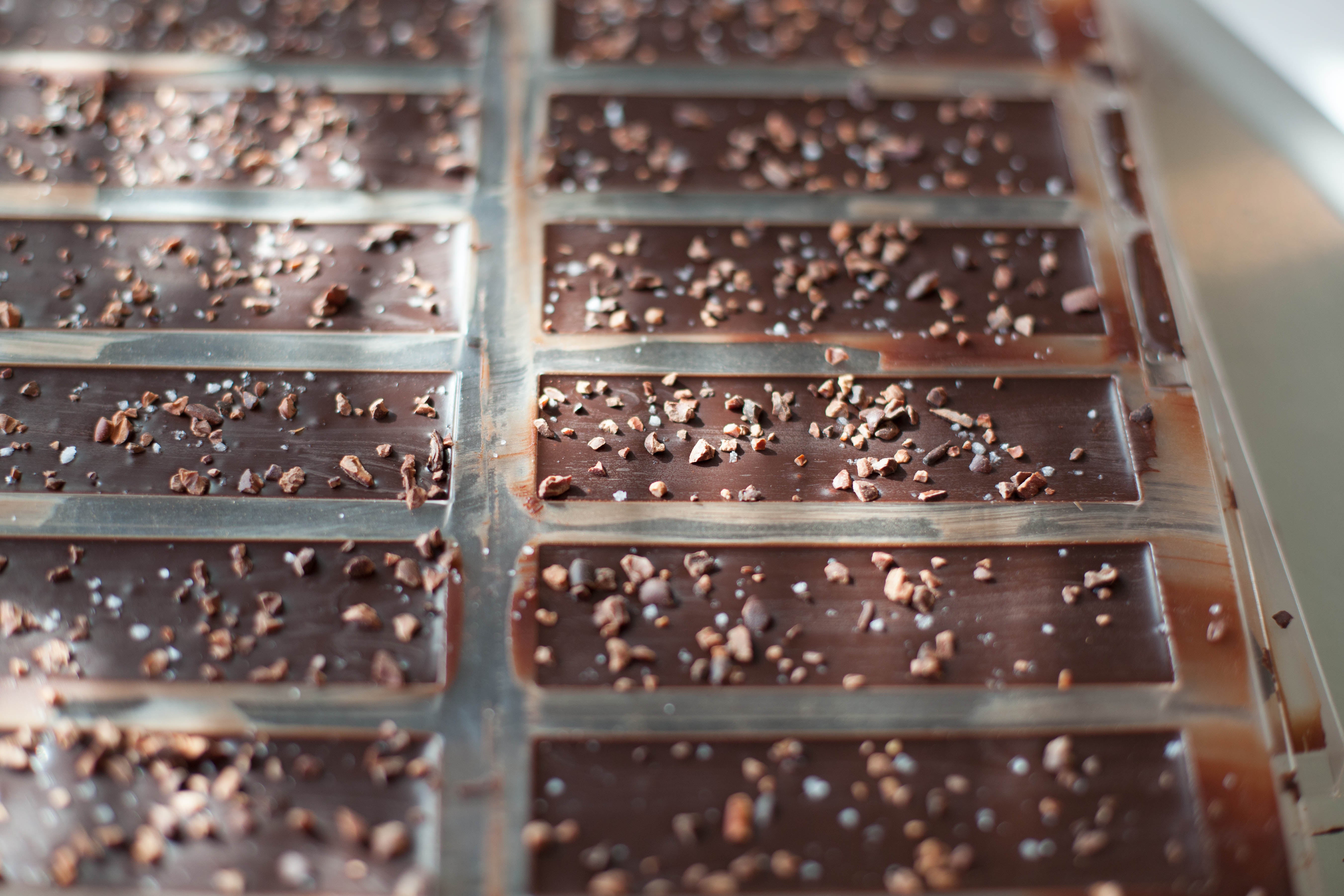

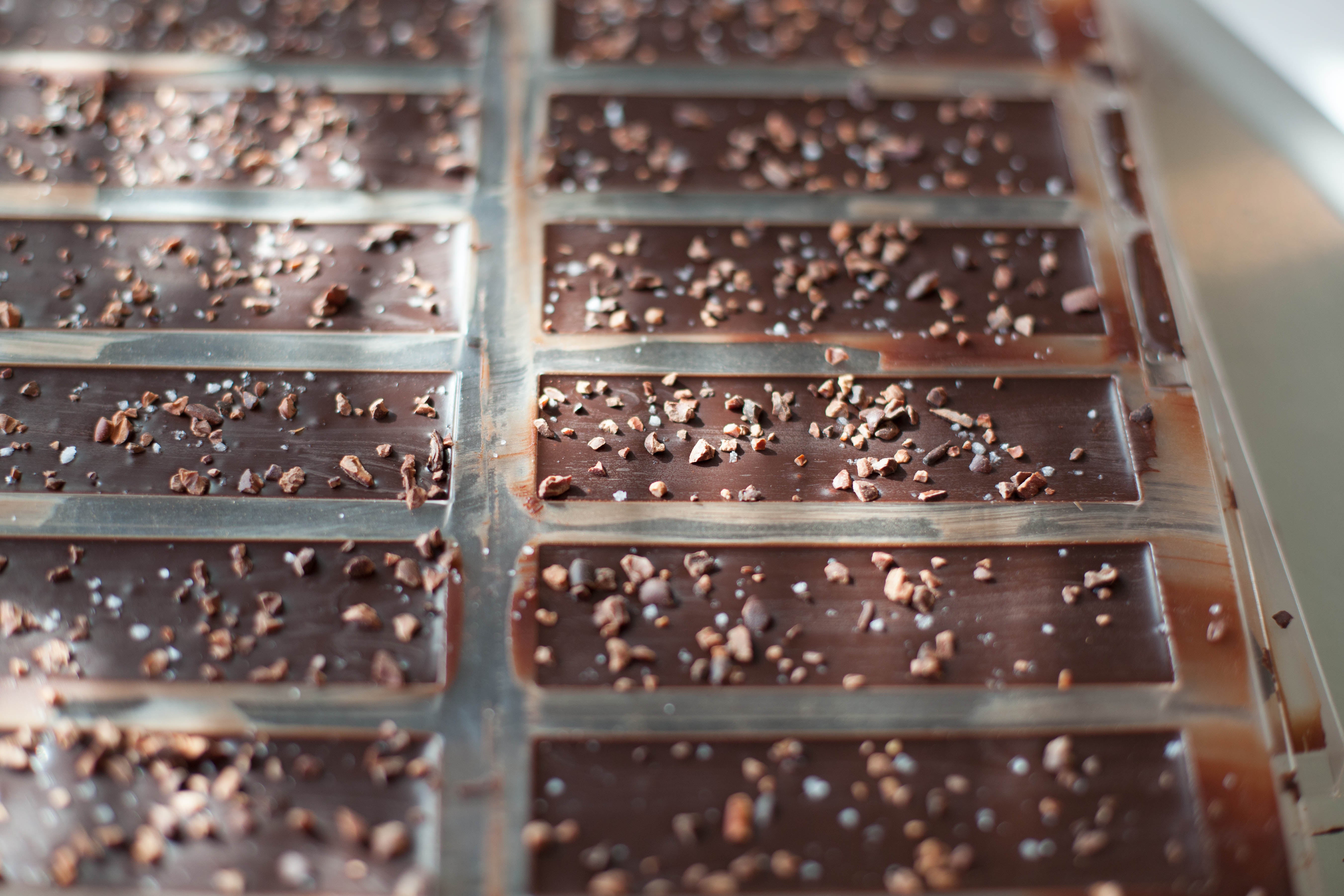

Temper

When the chocolate is ready, we temper it and pour it into molds to get our bars. This process gives the chocolate structural integrity, a shiny finish and a sharp snap when you break off a piece.

Wrap

Hand-wrapping provides a platform for us to sit and smile at each other while we work.

Eat

Woodblock Chocolate is better when eaten.